Sümerbank

Character Size

Sümerbank

I

SÜMERBANK

"To establish and manage the basic industries in Turkey" due to the need for a strong institution that can take the leading role in the industry in line with our national needs and interests in order to ensure that the industrialization movement is carried out in a more efficient and integrated manner by using all the national resources and economic elements of the country in the first years of the modern Turkish Republic. Sümerbank, named after the great leader Atatürk, was established on 11 July 1933 in line with its main purpose.

Sümerbank, Turkey's "industry school", is a state-owned economic enterprise affiliated to the ministry of industry and technology, with its legal personality and independence within the limits specified in its private law, its responsibility limited to its capital, fully owned by the state, subject to private law to operate in the economic field according to commercial principles. . To carry out our national needs and interests in an efficient and harmonious manner, to prepare and manage the studies and plans of all established institutions, to extend credit to established and to be established industrial institutions, to develop the Turkish economy, to increase the welfare of the people, to establish the economic infrastructure of Turkey's political independence,

The duties assigned to Sümerbank, which left its mark on the Turkish economy;

" -To operate the factories to be taken over from the State Industry Office and to manage the State participation shares in private industry institutions in accordance with the provisions of the Commercial Code,

- To prepare, establish and administer the studies and projects of all industrial institutions to be established with state capital, excluding the factories to be built on the basis of permissions granted by special laws,

- To participate or assist industrial enterprises whose ventures or growth are economically productive for the country to the extent permitted by their capital,

- To educate students in high schools in order to train the masters and workers necessary for the country and their own factories, or to help the schools to be opened by the economics power of attorney for this purpose, and to send students and interns to foreign states,

- To provide loans to industrial institutions and to carry out general banking works,

- To seek the necessary measures for the development of the national industry and to provide information on this issue and on the issues to be submitted to the Bank for examination by the Ministry of Economy.

With the law numbered 2262 dated 11 July 1933, with the aim of investing, establishing, operating and banking in the fields of manufacturing industry, especially in the textile and clothing industry, and carrying out production, marketing, export and import services of all kinds of goods and services, the entire capital of 20 million TL was transferred to the treasury. was established to meet. With the law numbered 3460, which entered into force in 1938, it was brought into the position of an economic state enterprise. Its main duties are: to prepare and establish studies and projects of factories and other industrial and commercial facilities related to their working subjects; to produce all kinds of finished products, semi-finished products and raw materials; to purchase and sell industrial inputs from the country or abroad when necessary; In order to ensure that bank resources are used in accordance with the objectives of the development plan and annual programs and that the selective credit policy is implemented effectively, banking, credit transactions, loan transactions, insurance agency in the fields of activity, especially in the textile, clothing and leather industry, and, when necessary, to open branches abroad, to establish representative offices, to participate; selling and purchasing information and technology, providing engineering and consultancy services.

The note he wrote in the factory honor book at Sümerbank Bursa Merino Factory. (February 2, 1938)

"The Sümerbank Merino Factory, as a very valuable work, will increase national joy. This work will help the industrial development of the country, especially the Bursa region, and to meet the great national need. I congratulate the Ministry of Economy on the achievement of the work. Thanks to the Sümerbank directorate and high knowledge as I saw the factory, full I wish success to the director in the regular administration." K. Ataturk

The central organization of the institution consists of the board of directors, the general directorate, the advisory board, the technical advisory board, the education board, the disciplinary board, the advertising and propaganda board, and the credit board. Advisory units consist of consultants, inspection and control directorate, legal consultancy, research and planning directorate, and the main units are wool, cotton and chemical industry directorates, chemistry and textile project directorates, banking and credit affairs directorate, purchasing directorate, subsidiaries directorate. Auxiliary units consist of the following parts: construction, machinery and energy, facility, personnel general accounting, education, social affairs, conjuncture and publication, personnel mobilization, mobilization of main tasks, civil defense statistics department directorates.

Industrial investments to which Sümerbank will participate and which are given priority in terms of the country;

a) Industries whose raw materials are grown in the country but whose production is not sufficient,

b) Industries that increase their value by processing unprocessed export goods,

c) Industrial branches whose raw materials are not available in the country although they are consumed to a large extent in the country, but whose raw materials can be grown throughout the country if they are established,

d) These are the branches of industry whose raw materials cannot be found in the country and cannot be grown, but their production will bring significant gains to the country.

Sumerbank; It has served in our country in the fields of Wool group management, Cotton weaving management, Leather and Shoe Group management, Carpeting, Chemistry, Porcelain, Apparel, Banking and Agriculture sectors. If we look at these areas in general terms by making a city-business comparison:

1) AGRICULTURAL SECTOR; It has developed every year with the continuous increase in the inputs used, the motor vehicles used, and the advanced agricultural technologies. With an average of 4% development every year, 60% of the total population benefited from this enrichment. In wheat and grain production, the increase in total production by 4 times every twenty years is the source of confidence in the future. Wheat production, which was 4 million tons in 1940, increased to 8.4 million tons in 1960 and 16 million tons in 1980. Increases in rice, sugar beet, sunflower and cotton production were even higher.

2) COTTON WEAVING MANAGEMENT; Turkey is a cotton country. He is a master of cotton weaving in Sümerbank. Turkish cotton with good qualities; has become the world-renowned Sümerbank cottons in its 19 facilities with a total spindle count of 486,444. It has developed on the knowledge and cultural heritage of centuries by adding contemporary techniques and international standards. It can produce an average of 276 million meters of cotton weaving and 69,000 tons of cotton yarn every year on 7387 weaving looms, with 24,594 personnel in 18 contemporary cotton weaving facilities. Total cotton yarn production is 16.4% of Turkey's total cotton yarn production, and total cotton weaving production is 16% of Turkey's cotton weaving production.

2.1- ADANA Cotton industry establishment; Adana Cotton Industry, which was acquired by Sümerbank in 1946, is one of Turkey's modern cotton businesses. The business consists of cotton yarn and cotton weaving units. The yarn production in the yarn unit is made over a minimum of 8 and a maximum of 40 “NE”. The reed width of the weaving looms used is 130 cm. with 180 cm. between. Dornier, Sulzer and Ruti looms are used in weaving units.

2.1.1- Products; The main products produced are weaving yarn and hambez.

2.2- ADIYAMAN Cotton industry establishment; It was put into operation in 1967. There are weaving yarn, knitting, combing and ready-made garment units in the enterprise. Yarn production in the yarn unit is made over a minimum of 12 and a maximum of 30 “NE”. Knitwear capacity reaches 1,690 tons per year.

2.2.1- Products; Among the main products produced are weaving yarn, undergarments such as singlets, undershirts, slips, and T-Shirts. It can produce 14 million pieces of ready-to-wear products per year.

2.3- BAKIRKOY Cotton industry establishment; It was established in 1850 and transferred to Sümerbank in 1933. It is one of Sümerbank's oldest and most well-established institutions. There are weaving and ready-made clothing units in the enterprise. Reed width of weaving looms 110 cm. with 130 cm. is The types of benches used are eccentric and dobby benches. Weavings are subjected to mercerization processes in order to ensure the brightness of the woven products produced.

2.3.1- Products; bed covers, bread bags, water bottles, awning cloths, tarpaulins, cheesecloths and hamcloths. Especially thick type tarpaulin weavings meet military needs. Shirts in various colors, pajamas, trousers, jackets and suits can be counted as ready-to-wear products.

2.4- DENİZLİ Cotton industry establishment; It was established within the body of Sümerbank in 1953 and became an institution in 1976. It has yarn and raw weaving units. Yarn production is made on a minimum of 6 and a maximum of 20 “NE”. The comb width of the benches used is 102 cm. is

2.4.1- Products; weaving yarn, raw cloth and dust cloths.

2.5- DIYARBAKIR Cotton industry establishment; It was put into operation in 1978. It largely meets the cotton yarn requirement of Sümerbank's other establishments. Yarn production is made over a minimum of 12 and a maximum of 20 “NE”.

2.5.1- Products; cotton yarn is produced.

2.6- EREĞLİ Cotton industry establishment; It was put into operation in 1937. The business consists of ready-made clothing and yarn weaving units. Weaving production is made on a minimum of 8 and a maximum of 60 “NE”. The reed width of the weaving looms is 180 cm. is Dornier type loom is used in the weaving unit.

2.6.1- Products; Raw cloth, alpaca fabric, hasse, gabardine, etamine, trench coat fabric and sewing thread are produced in yarn and weaving units. school aprons, work clothes, overalls, work jackets and trousers, work shirts and caps are produced.

2.7- ERZİNCAN Cotton industry establishment; The yarn unit of the establishment was put into operation in 1954 and the weaving unit in 1964. It consists of yarn production and weaving units. Yarn production is made over a minimum of 8 and a maximum of 12 “NE”. The comb width of the benches used is 105 cm. is

2.7.1- Products; weaving yarn and raw fabric. The most used type of raw cloth produced is burlap, which is used in large packages.

2.8- ESKİŞEHİR Cotton industry establishment; Yarn weaving units in 195 and printing units in 1966 were put into operation. The business consists of yarn production, weaving and printing units. Yarn production is made on minimum 8 and maximum 36 “NE”. The reed width of the weaving looms is 115 cm. with 130 cm. varies between The type of loom used in weaving production is Dornier. The printing techniques used are film printing, rotary printing and roll printing.

2.8.1- Products; polyester print, poplin print, flannel, satin upholstery, satin prints. The products attracted attention both in the domestic market and in the foreign market.

2.9- İZMİR Printing industry establishment; It was put into operation in 1953. The establishment consists of yarn production, weaving and ready-made clothing units. Yarn production is made over a minimum of 6 and a maximum of 30 “NE”. The comb width of the benches used is 115 cm. is Roll printing, rotation printing and film printing techniques are used as printing techniques.

2.9.1- Products; prints in various colors and patterns, upholstery fabrics, flannel, diptins can be counted. In the ready-made clothing unit; women's clothes, men's pajamas, shirts, as well as sheets, duvet covers and complete bedding sets are produced.

2.10- KAHRAMANMARAŞ Cotton industry establishment; It was put into operation in 1963. He transferred to Sümerbank in 1968. Institutional yarn production, cotton weaving and apparel production units are available. Yarn production is carried out over 20 “NE”.

2.10.1- Products; weaving products; hambez and hasse, in the garment unit; sheets, pillowcases, duvet covers and duvet cover sets.

2.11- Sumerbank with these regions; It has served with cotton industry establishments in Karaman, Kayseri, Malatya, Nazilli and Nevşehir.

3) WOOL INDUSTRIAL ORGANIZATIONS; Each year, an average of 8,824 tons of wool yarn and 7.6 million meters of pure wool were produced in 5 contemporary enterprises with a total number of spindles of 40,539 and a total number of looms of 534. 5 of the 10 establishments, factories and subsidiaries in the wool industry group consist of wool yarn and wool weaving units and 5 of them are carpet weaving units. In the Sümerbank woolen group, where a total of 5,526 people work, fabrics for men's and women's costumes, wool and mohair blankets, wool draperies and upholstery are produced. Clothing for women, men and children are produced in ready-made clothing units. Sümerbank's woolen yarn and woolen production account for 8% of Turkey's total wool yarn production and 14.4% of woolen weaving production.

3.1- DEFTERDAR Wool Industry Establishment; It is one of the oldest established wool weaving factories in Turkey. It was established in 1836 as FESHANE (fez workshop). The factory, which was taken over in 1933 with the establishment of Sümerbank, has met the needs of the armed forces, various official institutions and the entire nation for clothes, coats and serge fabrics, and later on, a woolen ready-made clothing unit was added to its structure. The establishment consisted of wool yarn production, wool fabric weaving and mainly woolen garment units.

3.1.1- Products; Among the woolen fabrics produced, serge fabric, overcoat fabric and serge fabric can be counted. As woolen ready-made clothing, they are single trousers and jackets, as well as suits.

3.2- HEREKE Wool Industry Establishment; Founded in 1843, it is one of the oldest institutions in Turkey. It was incorporated into Sümerbank in 1933. With woolen yarn production, wool weaving and silk weaving units; It consists of facilities that manufacture daily use items from these weavings.

3.2.1- Products; fancy dress fabrics such as flannel, blaizer, fresco, tweet, serge, fabrics for jackets, coats, coats and various weavings can be counted.

3.3- MERİNOS Wool Industry Institution; The foundation of Sümerbank Merino Wool Industry Institution (Bursa) was laid on 28 November 1935. The enterprise was put into operation by Atatürk on February 2, 1938. He wrote the following in the honor book of Atatürk Merino Factory: “The Sümer Bank Merino Factory, as a very valuable work, will increase national joy. This work will help the industrial development of the country, especially the Bursa region, and to meet the great national need.” In 1985, 3018 workers and 130 civil servants were working at the workplace. The business was closed on 23.9.2004. The land, land and real estates belonging to the enterprise were transferred to Bursa Metropolitan Municipality on 25.10.2004.

3.3.1- Products; Apart from the worsted yarn used in production, tops, 100% wool fabric, wool polyester fabric, wool viscose fabric, wool-viscose-polyester fabric, overcoat and topcoat fabrics are the leading products. In the field of ready-made clothing; summer and winter suits, scotch jackets, summer and winter men's and children's trousers and coats are produced.

3.4- TAŞKÖPRÜ Hemp Industry; Sümerbank Taşköprü Kendir Sanayi was founded in 1947. In 1985, there were 391 workers and 35 civil servants at the workplace. It was transferred to TEKEL on 17.11.1995. TEKEL also closed this business.

3.4.1- Products; jute yarn

4) SUMERBANK CARPET WORKS; Sümerbank produces 2194 tons of carpets, hand and machine carpet yarns and 560,000 square meters of carpets with 1487 workers and officers in 4 carpet business establishments. hand-woven carpets; It adds new qualities to plain patterned machine carpets.

4.1- BÜNYAN Carpet Weaving and Blanket Industry Institution; Sümerbank Wool Industry Institution Bünyan Factory was founded in 1927 by Kayseri Bünyan Halı İpliği TAŞ. was founded under the name. The company started weaving production in 1933 and was transferred to Sümerbank on May 1, 1934. In 1982, its name was changed to Sümerbank Bünyan Carpet and Blanket Industry Institution. In 1985, 378 workers and 37 civil servants were working in the enterprise. The enterprise was privatized on 31.10.1997.

4.1.1- Products; is engaged in the production of wool and mohair blankets, fleece and various types of handmade carpets. To the establishment; Sivas, Kayseri, Kahramanmaraş and Malatya regional directorates of carpeting are affiliated, and the weaving and dissemination of carpets with local characteristics is ensured through the carpet workshops, individual weavers and carpet cooperatives in these regions.

4.2- DIYARBAKIR Carpet Industry Institution; Sümerbank Diyarbakır Carpet Industry Institution was put into operation in 1954. In 1985, 306 workers and 32 civil servants were working at the workplace. Diyarbakır Carpet Business, Pertek Wool Yarn Business, Isparta Carpet Business and Hereke Carpet Business were combined and Sümer Halı A.Ş. was created and this enterprise was transferred to the Ministry of Industry and Trade on 21.1.1998.

4.2.1- Products; plain and various patterned machine rugs.

4.3- HEREKE Carpet Industry Institution; Established on January 1, 1986, the institution continued its carpet weaving activities in the form of workshop production and dissemination of cooperatives with the Çanakkale, Yozgat and Niksar carpeting regional directorates.

4.3.1- Products; hand woven silk fabric.

4.4- ISPARTA Carpet Weaving Establishment; In order to meet the carpet yarn need in the Isparta region, the foundation of a factory was laid in 1924 with the joint venture of the Turkish Industry and Maadin Bank and Isparta carpet makers, and the factory was put into operation in 1926. In 1933, this company was liquidated and in 1943 it was purchased by Sümerbank and transformed into Sümerbank Isparta Carpet Shop. In 1985, 305 workers and 106 civil servants were working in the enterprise.

4.4.1- Products; carpet yarn and hand-woven carpets.

5) LEATHER AND SHOE FACILITIES; In this industry branch, Sümerbank employs a total of 3196 personnel, annually 6.9 million women's, men's and children's shoes, military boots; It has a production capacity of 750 tons of leather, 100 million square meters of screws, 1200 tons of artificial leather, 4 million meters of synthetic leather and 9000 tons of valex.

5.1- BEYKOZ Leather and Shoe Industry Enterprise; Sümerbank Beykoz Leather and Shoe Industry Institution was founded in 1812 by the II. It was bought (nationalized) from the private sector by Mahmut. The factory was transferred to the Turkish Industry and Mines Bank in 1925; In 1933, it was connected to Sümerbank. In 1985, 1826 workers and 102 civil servants were working in the enterprise. A decision was made on 12.10.999 to close the business. However, as a result of the resistances led by Deri-İş, the decision to close could not be implemented. The enterprise was privatized on 14.4.2005.

5.1.1- Products; leather, screw, artificial leather, various types of shoes other than rubber production.

5.2- VAN Leather and Shoe Industry Enterprise; Sümerbank Van Leather and Shoe Industry Institution was established in 1982. In 1985, 292 workers and 38 civil servants were employed. The workplace was closed on 02.12.2004.

5.2.1- Products; Summer and winter men's shoes, men's slippers are produced with a capacity of 1 million per year.

6) ADANA PURCHASING COTTON AND GINTING FACTORIES; Sümerbank was founded in 1949. It took place within the body of Sümerbank in order to meet the cotton needs of cotton establishments by purchasing and processing the unseeded cotton in the Adana region, which can be considered as Turkey's cotton warehouse. The establishment has 2 ginning facilities, one in Adana and the other in Ceyhan.

6.1- Products; ginned cotton obtained from seed cotton.

7) GEMLIK SUNGIPEK AND VISCOSE PRODUCTS INDUSTRIAL ENTERPRISE; Sumerbank Gemlik

The foundation of Sungipek and Viscose Products Industry Institution was laid on 28 November 1935 and the factory was put into operation by Atatürk on 1 February 1938. In 1985, 626 workers and 85 civil servants were employed in the enterprise. The business was transferred to TEKEL on 16.3.1998. TEKEL also closed this business.

7.1- Products; produces lacquered and unlacquered cellophane, white, matte and colored viscose.

8) TARSUS FABRIC PAINT INDUSTRIAL ENTERPRISE; Sümerbank Tarsus Textile Dyes Industry Institution was put into operation in 1966. In 1985, 214 workers and 48 civil servants were employed at the workplace. The business was closed on 10.10.2000.

8.1- Products; manufactures fabric dyes consisting of azo and sulfur dyes.

9) YILDIZ TILE AND PORCELAIN INDUSTRIAL ENTERPRISE; It was established in the garden of Yıldız Palace in 1892 to meet the tile and porcelain needs of the Ottoman palace. It takes its name from here. Yıldız Tile Plant was transferred to the National Palaces Department of the Grand National Assembly of Turkey on 10.07.1995.

9.1- Products; technical and hand-decorated porcelain ornaments and tableware, various vases, wall plates, wall panels, trinkets, fireplaces, dinner sets, asure bowls, soup bowls, cup bowls are produced.

10) SUMERBANK BANKING; The financial resources required by the investment activities of Sümerbank and its factories were provided by Sümerbank's banking services. Sümerbank, with its 44 branches spread over 29 cities in the country, not only ensures that the domestic and international banking services of its own institutions can be seen quickly, but also improved all banking services and served in the collection and evaluation of savings. 629 personnel worked in Sümerbank's banking service.

10.1- Sümerbank Branches Spread throughout Turkey; Adana, Antalya, Aydın, Bahçekapı-Istanbul, Balikesir, Beyoglu-Istanbul, Bolu, Cebeci-Ankara, Ceyhan-Adana, Demirci-Manisa, Denizli, Diyarbakir, Elazig, Eregli-Konya, Erzincan, Eskisehir, Esrefpasa-Izmir, Gaziantep, Isparta, Iskenderun, Istanbul, Izmir, Izmit, Kadıköy-Istanbul, K.Maras, Karabuk-Zonguldak, Karsiyaka-Izmir, Kayseri, Konya, Malatya, Manisa, Merinos-Bursa, Center-Ankara, Mersin, Nazilli-Aydin, Ordu, Rize, Samsun, Sivas, Şişli-Istanbul, Tarsus-Mersin, Yenişehir-Ankara, Zonguldak.

11) FACTORIES AFFILIATED TO SUMERBANK INSTITUTIONS

11.1- ÇANAKKALE Synthetic Leather Factory; Çanakkale Synthetic Leather Factory was established in 1982. In 1985, 181 workers and 44 civil servants were working in the enterprise. The factory was privatized on 27.10.2004.

11.1.1- Products; synthetic leather and synthetic leather products such as school bags, suitcases, tents, raincoats, automobile covers made from this leather.

11.2- PERTEK Carpet Yarn Factory; He works as a subordinate of Bünyan Carpeting and Blanket Industry.

11.2.1- Products; factory 2-6 Nm. Strayhgarn manufactures yarn.

11.3- SALİHLİ Bonito and Valeks Factory; Sümerbank Salihli Bonito and Valeks Factory was established in 1955 and transferred to Sümerbank in 1961. In 1985, 50 workers were working in the enterprise. The factory was privatized on 29.5.1998.

11.3.1- Products; produces valex, which is used as a tanning agent in the leather and leather industry.

11.4- SARIKAMIŞ Shoe Factory; Sümerbank Sarıkamış Shoe Factory was put into operation in 1983. In 1985, 282 workers and 30 civil servants were working in the factory. The business was closed on 02.12.2004.

11.4.1- Products; manufactures military and civilian boots.

11.5- TERCAN Shoe Factory; Sümerbank Tercan Shoe Factory was put into operation in 1983. In 1985, 325 workers and 26 civil servants were working in the factory. This business was also closed on 02.12.2004.

11.5.1- Products; produced women's shoes, women's slippers, women's boots and nurse type shoes.

12) SUBSIDIARIES OF SUMERBANK

12.1- ANTALYA Cotton Weaving Industry TAŞ. General Directorate; 81.6% of Antalya Pamuklu Dokuma Sanayii TAŞ.'s shares belonged to Sümerbank and the company had been operating under Sümerbank since 1961. In 1985, 1025 workers and 73 civil servants were working in the enterprise. The business was closed on 23.09.2004 and its assets were transferred to Antalya Kepez Municipality on 10.2.2005.

12.1.1- Products; minerpolin produced poplin pajamas, handkerchiefs for men and women in various colors and patterns.

12.2- BERGAMA Cotton Yarn and Weaving Industry TAŞ. General Directorate; Bergama Cotton Yarn and Weaving Industry TAŞ. It was put into operation in 1954. 72.3 percent of the company shares belonged to Sümerbank. In 1985, 1134 workers and 62 civil servants were employed in the enterprise. The enterprise was privatized in July 2005.

12.2.1- Products; produced cotton and cotton-polyester blend poplin shirting and pizamalik.

12.3- MANİSA Cotton Mensucat A.Ş. General Directorate; Manisa Cotton Mensucat A.Ş. It was put into operation in 1960. 84.5 percent of the company shares belonged to Sümerbank. In 1985, 1264 workers and 56 civil servants were working in the enterprise. Work on the privatization of the enterprise was initiated in July 2005.

12.3.1- Products; Apart from cotton yarn, trench coat, parka, white officer fabric and workwear were produced. In the field of ready-made clothing, it produced coats, trench coats and jeans.

12.4- TÜRKİYE Yapağı ve Tiftik A.Ş. General Directorate; Turkey Yapağı ve Tiftik A.Ş. It was founded in 1955 and joined Sümerbank in 1984. 99 percent of the company's shares belonged to Sümerbank. In 1985, 130 workers and 217 civil servants were working in the enterprise. The business was liquidated in 1995.

12.4.1- Products; In addition to its sorted, processed, washed and semi-finished products, it is the most important production of carpet yarn and mohair tops.

13) ORGANIZATIONS WITH SUBSIDIARIES OF SUMERBANK

13.1- Textile

13.1.1- Aydın Tekstil A.Ş.

13.1.2- Balikesir Cotton Doc. Singing. Inc.

13.1.3- SIDAŞ Sivas Doc. Singing. Inc.

13.1.4- Yifaş Yeşilyurt Tekstil San. Inc.

13.1.5- Güney Sanayi İşl. Inc.

13.1.6- Van Wool Yarn Industry Inc.

13.2- Banks

13.2.1- TR Central Bank A.Ş.

13.2.2- T. Emlak Kredi Bankası A.Ş.

13.2.3- T. Vakıflar Bankası TAO

13.2.4- T. Halk Bankası A.Ş.

13.2.5- T. Ticaret Bankası A.Ş.13.2.

13.2.6- DESİYAB

13.3- Chemistry

13.3.1- T. Fertilizer Industry Inc.

13.3.2- Basf-Sümerbank T. Kim. Singing. Inc.

13.3.3- T. Petrolleri AO

13.3.4- SİFAŞ Cent. Ipl. Fab. Inc.

13.3.5- Soda Sanayi A.Ş.

13.4- Soil

13.4.1- T. Çimento Sanayi TAŞ.

13.4.2- Kütahya Porselen Sanayi A.Ş.

13.4.3- TUG-SAN Gemerek Tic. Singing. Inc.

13.5- Iron-Steel

13.5.1- Eregli Demir Çelik Fab. STONE.

13.5.2- Mannesman-Sb. Boron. end. STONE.

13.6- Other Miscellaneous

13.6.1- Cyprus Holding

13.6.2- GENTAŞ Gen. Met. Singing. Inc.

13.6.3- Public Stores TAŞ.

13.6.4- GIMA

13.6.5- Oralgim Avg. Moment. Wear. Singing. Inc.

13.6.6- Türk Pazarlama A.Ş.

13.6.7- Güven Sigorta A.Ş.

13.6.8- T. Şeker Fabrikaları A.Ş.

In 1987, within the framework of the Law No. 3291 on the Privatization of State Economic Enterprises, the privatization of Sümerbank was decided by the decision of the Council of Ministers, and the relationship of the institution with the ministry to which it was affiliated was cut off and it was subordinated to the Prime Ministry in terms of administration. All of the state-owned shares in Sümerbank were transferred to the mass housing and public partnership administration without charge. In February 1989, a preliminary consultancy agreement on how to structure the sale of Sümerbank was signed between the foreign consultancy companies Barclays, De Zoete Wedd, Coopers, Lybrand and the International Industry and Commercial Bank Consortium and the mass housing and public partnership administration.

Sumerbank; It has been an important institution of the Republic of Turkey both in the field of industry, in the field of textile and banking, and with the contributions it has made to the country's economy, the business opportunities it has offered to the citizens of the country and the quality goods it has produced, with the facilities and factories it has established in different business areas and in many different regions of the country, and in its development period, besides providing benefits with its export share in the world economy, it is a very important point that it can be easily observed that it has become a world brand.

Prepared by: Ökkeş Narinç, Kilis 2009 Kilis 7 Aralik University Institute of Social Sciences

Source:

http://www.ydk.gov.tr/kit99/Birinci_Bolum.htm

http://www.ekodialog.com/kamu_maliyesi/kamu_iktisadi_kuruluslari.html

http://www.hukuki.net/kanun/233.45.text.asp

http://www.millidusunce.com/index.php?option=com_content&task=view&id=47&Itemid=1

COMMISSION, Dictionnaire Larousse Encyclopedic Dictionary, Sümerbank Article, c. 6., Milliyet Press, 1993.

COMMISSION, Great Larousse Dictionary and Encyclopedia, Sümerbank Article, c. 21, Milliyet Publishing.

COMMISSION, Turkish Encyclopedia, Sümerbank Article, c. XXX, MEB Publishing House, Ankara 1981.

COMMISSION, Meydan Larousse, Sümerbank Article, c. 18, Sabah Publishing, October 1992.

INDUSTRIAL SCHOOL SUMERBANK, Sümerbank Magazine, Kilis 7 Aralik University Mehmet Sanli Library.

TUNA, Serkan, State Enterprises in Turkey (1930-1940), PhD Thesis, Istanbul 2002.

II

NAZILLI COMBINE

The country has gained a work that works for the nation.

The train has been moving through the fertile, wet and green valley since morning. The mountains rising slightly from both sides have chosen the best as the owner of these places, which have been shaped by the curves that nature has worked with the most care. This homeland is the sacred land of the Turk! We were approaching Nazilli, Atatürk asked H. Reşit Tankut:

- “What does Nazilli mean?”

Before his explanation was finished, young, loud voices filled the train. The voices of today's children of ancient ancestors were humming and ringing like voices from the vast depths of history: "Long live Atatürk!"

The excitement, strengthened by these heartfelt voices, engulfed Atatürk even more when he landed at the station. He was advancing with the steps that represented his will, on top of the great works he had done for his country.

Atatürk went to the People's House with the applause of the people of Nazilli surrounding him. There was talk of the big issue of the day. Prime Minister Celal Bayar talked about a speech that took place in this hall six years ago. The subject was on the principle of statism with a free regime. At that time, there was talk of establishing a factory in Nazilli.

Atatürk and the country's elders are in this town for this work that took place today. Small wagons were boarded, and a little further from the city, the road was made towards the factory combine. We were just beginning to see this work, based on an item from the Republican government's First Five-Year Industry Program. The roads leading to the factory buildings were full of people. The crowd that joined Atatürk's path took place in the square. The entrance to the first building was through cotton twigs that little children kept in baskets. We all decorated our collars with these cotton twigs.

In this building, we were listening to the valuable explanations of the factory manager. From the first pushes, a ball was placed on the table. This ball is tied with red and white ribbons; What a lot of meanings it meant as a valuable part of Turkish cotton. The Turks will wear their own goods by adding manual labor to the productivity of their own lands, but these labors will get the most share from the advanced inventions of this century, which are mechanized. Turkish handicrafts no longer occupy a place only on hand looms. It needs staff to meet the needs of today's life. The Nazilli factory is an example of this need. The shape that the combination would take when it was completed was determined by lines on the map on the wall. Today, the unfinished places were only the garden and park parts.

The speech on behalf of the city was heard from the balcony. Celal Bayar revived this work, one of the practices of the İnönü government, with absolute numbers. This speech was full of economic expressions of work done on the basis of the principles of statism.

When the speech was over, Turkish workers, men and women, who were going to dress the Turk, made a parade in front of Atatürk. The female workers, dressed as a model, were vivid symbols of cooperation in the Turkish homeland. Kayseri Factory's sports club also took part in this ceremony.

According to the plans given to us, we came to the front of the first part. Atatürk opened the door with a key made of yellow metal with the letters Sümerbank, tied with a red ribbon. Everyone went in. The temperature outside had given way to coolness, following the course of technical development in this building.

We are walking under the guidance of the factory director… Cotton takes various forms in working machines; threads were clustered on thousands of spools… The spools were untied and took place on the looms, in a big hall where the looms were located, a worker standing at each machine was waiting for the order of “Start” .

Addressing Atatürk, the director said, “They are waiting for your order to operate.” said.

The order from the great ground suddenly put 480 machines into noisy activity.

Then Atatürk said:

“Here are the voices that will bring prosperity to the people.”

Every machine worked under the command of its worker. The fabrics were woven, washed, colored, finally reaching the modern technique of chemistry and adorned with colorful flowers. Red, blue, every color that pleases the eye was included in these prints.

Here we also learned something. Every region of Anatolia has a color choice. That's why the Turkish artist has to appeal to Turkish tastes, both in colors and in the choice of flowers. Everyone was delighted and joyful at this work, because the country had won a work that worked for the nation, for its pleasure, and finally for one of its most inescapable needs.

Source: Memories and Documents About Atatürk, Afet Inan, 5th Edition Prepared by Arı Inan, Türkiye İş Bankası Cultural Publications 2007, ISBN: 978-9944-88-140-1. Page: 230-233

III

GIANT PROJECT OF THE REPUBLIC: NAZİLLİ SUMERBANK PRINTING FACTORY

The factory that inspired the “Atatürk Model Factory” 1 in Venezuela is the Nazilli Sümerbank Printing Factory, opened by Atatürk in 1937. Nazilli Sümerbank Printing Factory is very important as it is the first implementation of the “Social Factory Project” in Atatürk's mind. The factory in Atatürk's mind is not only a place where production is made, but also a laboratory where "R&D" studies are carried out, a school where education is given, a cultural complex with all kinds of arts and sports facilities, in short, a complete "living space". is a campus. Atatürk was planning to build these “social factories” all over Anatolia, where the workers benefited from all kinds of opportunities at high standards. But his life would not be enough to popularize this project.

Nazilli Sümerbank Printing Factory is the first important work of the First Five-Year Development Plan of the young Republic. It is the first Turkish printing factory established by Sümerbank. It is the first printing factory established by the state.

Nazilli Sümerbank Printing Factory is the first important work of the First Five-Year Development Plan of the young Republic. It is the first Turkish printing factory established by Sümerbank. It is the first printing factory established by the state.

The factory is a Turkish-Soviet co-production. Most of the machines and equipment were bought from the Soviet Union in exchange for citrus. He employed 120 Soviet fitters and engineers to fill the labor shortage in the factory establishment.

The foundations of the factory were laid on August 25, 1935, its construction was completed in 18 months and opened on October 9, 1937. Including the building and machinery, it cost 8 million liras.

It is planned for the factory to start working with 28 thousand spindles and 800 automatic looms and to process 2,400,000 kilos of yarn. With this, 20 million meters of compression will be produced.

The factory will burn 15 thousand tons of coal.

The factory will employ a maximum of 2400 workers every day and will pay 1 million lira per year as wages.

The factory consists of five parts: Weaving section, Printing section, Pattern section, Engraving section and Printing section. Daily weaving is between 62,000 and 64,000 meters. There are 4 printing machines in the printing section. There will be an average of 85,000 meters of printing per day in different colors and patterns.

Nazilli Sümerbank Printing Factory has a “social” quality that is not seen in the world, including in socialist countries. Yes, the Soviet model was taken as a basis when establishing the factory, but the young engineers of the young republic managed to produce a very original work unique to the Turkish revolution. Nazilli Sümerbank Printing Factory is a unique “socio-cultural” economics project, unlike anything else in the world of the 1930s.

Here are the surprising features of the Nazilli Sümerbank Printing Factory:

1. The factory organized balls, dances and parties: The people, who did not attend any meeting of men and women until the mid-1930s, socialized with the balls, dances and parties organized by the factory, especially women began to come to the fore.

2. There is a movie theater in the factory: In 1937, a movie theater with a capacity of 700 people was opened in a city where 12 thousand people lived. Films were shown twice a week to civil servants, twice to workers, and twice to masters.

3. Factory established Community Center: The factory established a community center called “Sumer Community Center” and tried to raise awareness of the public on every issue. The first and only community center opened within a factory is the Sümer Community Center. The majority of the employees in the branches of the Community Center are factory workers. The Community Center has a stage inside the factory to display the plays it has prepared. Every year, many young girls have had a job in the Sumer Community Center cut-sewing courses. The Community Center organized trips to the surrounding villages, dealt with the problems of the villagers, sent medicines and health personnel to the villages and provided the treatment of the patients.

4. The factory has a choir: A musical group is formed among the factory workers. Performing classical music, the group gave concerts in Nazilli, Aydın and Denizli, making “polyphonic” music known in Anatolia. This choir (group), which reads works from world classics between meals in the factory, enabled the workers to reach Beethoven pleasure. There is also a piano in the factory, open to the use of workers who know how to play.

5. The factory has a bath: A bath established within the factory served both the workers and the people of Nazilli.

6. The Factory has Painters: The designers in the factory went out of the factory at certain times and made beautiful pictures of Nazilli and its surroundings. These paintings made by factory painters were sold at auctions. The factory, which also organizes painting and sculpture exhibitions, enabled the development of fine arts in Nazilli.

7. The factory has a sports club: The navy blue-white colored Sümer Spor, established within the factory, has been active in the branches of football, basketball, athletics, volleyball, cycling, wrestling, swimming and boxing. Sümer Spor football field within the body of the factory is one of Turkey's first “bottom-heated” football fields. Also within the factory, there are basketball and volleyball courts, wrestling mats, boxing ring, tennis court and skating rink. “Skating entertainments” and “bike races” that strengthen social cohesion in Nazilli are the legacy of the Nazilli Sümerbank Printing Factory.

8. The factory distributed free print to the public: The Nazilli Sümerbank Printed Factory, designed as a social factory, distributed “throwaway” to the public every six months.

9. Workers' rights are at the highest level in the factory: The factory, which houses a large number of workers, also attaches great importance to workers' rights. Worker and Servant Saving Funds, Worker Death and Harvest Benefit Funds were established, a 40-bed hospital, a pharmacy and a laboratory were established within the factory to protect workers' health. Malaria, which became Nazilli's nightmare, was cured by the health team of the factory. The factory, where workers are given vocational training, also has a five-class literacy course for workers, or rather a small school. This worker's school, named Sümer Elementary School, has 980 students. In addition, a worker's radio and a 26-bed and 40-room nursery for workers' children were established. While the workers and civil servants stay in the specially built 264 flats and 1000-person lodgings right in front of the factory at a very affordable price, There is a 350-seat Single Worker Pavilion for single workers. A mini train called GIDI GIDI, which makes regular trips, was used to transport workers and civil servants who could not stay in the lodgings from the city to the factory. There is a cooperative within the factory to provide food and clothing for the factory workers. The factory has a nice and clean bakery serving the workers, a workers' cafeteria, an officer's canteen and a Turkish bath.

10. The factory has an R&D department: Before the factory was opened, 200 modern seed planting machines were purchased for the cultivation of quality cotton to be used in the factory. Again, many modern agricultural tools and machines were brought to the region to be used in the cotton business and distributed to the farmers and they were taught how to use them. In the R&D departments of the factory such as the mechanical room, the physics laboratory, and the agricultural laboratory, studies have been carried out to increase the quality of the production to be made in the factory.

11. The factory has a workshop: The factory has a large workshop. This workshop had a forge, a carpentry shop, a foundry, a part of welding and tin work. Machine strike arms, which needed wooden parts of other factories, were made here.

12. The factory has electricity and water power plants: The factory, for a period, provided both its own electricity needs and the electricity needs of the city of Nazilli with an in-house power plant. This power plant, which has four boilers and three turbines, has a power of 2500 kW. There is also a water plant to meet the water needs of the factory.

Here is the Nazilli Sümerbank Printing Factory… Here is the first application of Atatürk's “Social Factory Project”… Here is the view of the young republic towards its people, people and workers…

ATATÜRK AT NAZİLLİ SUMERBANK PRINTING FACTORY

Atatürk himself opened this first printing factory established by the state in Turkey on October 9, 1937. Atatürk came to the opening with the army commanders and administrators in the region for the Aegean maneuvers. Chief of the General Staff Marshal Fevzi Çakmak, Second Army Inspector General İzzetin Çalışlar, Deputy Chief of General Staff Asım Gündüz, Gendarmerie General Commander Naci İldeniz, General Inspector of Thrace General Kazım Dirik and İzmir Governor Güleç, Deputy Prime Minister Celal Bayar, İsmet İnönü, Deputy Afet İnanve. Peker, Deputy of Agriculture Şakir Kesebir, Deputy of Internal Affairs and CHP General Secretary Şükrü Kaya, Deputy Public Works Ali Çetinkaya, Deputy of Foreign Affairs Tevfik Rüştü Aras, Deputy of National Defense Kazım Özalp, Deputy of Finance Fuat Ağralı, Deputy of Culture Saffet Arıkan, Deputy of Customs and Monopolies Ali Rana,

The importance attached to the opening of the Nazilli Sümerbank Printing Factory, the first and last factory that Atatürk opened, is also evident from the participation of almost all state officials, whether military or civilian.

From the station where Atatürk, who was welcomed by the factory officials at the Nazilli Basma Factory station, to the factory directorate building, the people were lined up on both sides of the paved road in an orderly manner. The little girls in line greeted their guests with cotton branches in their hands and presented them to Atatürk. The factory building and squares are decorated with flags. When Atatürk came to the factory with his friends, he was greeted with great joy and cheer by the crowd in the company of the People's House Orchestra. Atatürk responded to this enthusiastic welcome of the people by greeting the people from the balcony of the directorate building at the entrance of the factory.

After the speeches made at the opening, Atatürk left the management office of the factory and came to the doors of the buildings where the yarn weaving and carpet machines are located. Atatürk, who saw an electrically illuminated bust in front of the factory's power plant, after examining this bust for a while, complimented the factory manager by saying "beautiful" and then inaugurated it. When Atatürk opened the factory, 480 machines started working at once and processed the first cotton. During the ceremony, a fleet of aircraft flew over the factory.

Nazilli Sümerbank Printing Factory, opened by Atatürk, changed the face of Nazilli in a very short time. Nazilli was one of the earliest and most radically enlightened cities, perhaps the first, within the scope of the modernization project of the young republic. The place of the Nazilli Sümerbank Printing Factory is very important in the “modernization” of Nazilli.

IMPRESSIONS OF BEDRI RAHMI EYÜBOĞLU

Poet and painter Bedri Rahmi Eyüboğlu, who came to Nazilli on October 7, 1953, observed the change in Nazilli as follows:

“… We passed six amusement parks in six hours… Let's see what the city is full of neon lights. What do you call Nazilli, isn't it a small accident in Anatolia? How can one not be happy to see an Anatolian town floating in light and electric light at twelve o'clock in the night… A zipper of light that brings together both sides of Nazilli extends all the way to the Basma Factory. A slightly greenish light instead of yellow. We walked under this light. A very polite officer, I couldn't quite tell whether he was a city official or a police officer, he called out to a little boy; He said, 'Take this guest to Gıdı Gıdı…'. At first I thought it was a neighborhood, a district name. Then I said that a chauffeur can be a coachman. What they call Gıdı Gıdı is a small, zany dekovil train. He used to carry the workers to the factory at certain times… If I had a cat, I would definitely name it Gıdı Gıdı… A few steps away, several hotels with the same lights were lined up. This is not an accident, I say provincial center. They say that the factory made this place like this.

A bus stops in front of the shop, many workers come out of it, most of them women. There are several men. They were returning from the factory. The Night Post. They don't look very tired, but it's clear that they haven't returned from the henna night either. They rush into the streets with unhurried steps. Most of them are wearing a white headscarf over black shirts. Wide roads, illuminated roads, illuminated hotels, shops open at midnight, rows of eucalyptus trees.

These days, when winter is at the door, the variety of vegetables in the market is astonishing... Don't worry that old houses look very calender from the outside, they are like heaven inside. Neatly clean. There is an abundance of bicycles in Nazilli. There are also motorcycles and outboard motor bikes. Most of the bikes must be from the workers at the Printing Factory. The factory has a bicycle garage. Because the road was straight, the workers adopted the bicycle.

This must be one of the blessings that the factory donated to Nazilli. What can I say, if I saw it in the cinema, I would say it was an advertisement. If they had told me that I saw five hundred workers going to work by bicycle in an accident center in Anatolia, I would not have easily lost my mind.

As I toured the factory, I was surprised to see the facilities and facilities provided to the workers. A hot, delicious, strong dish. Milk and yogurt for those who deal with paints, a hospital for workers, a kindergarten, a canteen, a garden as wide as possible, a pool above the canteen. A bronze statue, a statue of a woman, which I think was created by a sculptor in the pool. One of the workers did it. It was cast bronze at the factory. My God! In the academy, it is not possible to cast it on plaster, not bronze. They also set up a soda counter. Its income is given to the workers' sports club. There are football teams. He did not fall behind anyone in the matches he played in Denizli.

There is a theater of a rare size in Istanbul. They played 'The Heist' recently. Some weddings were held here because there was no such hall in the city. Not missing at proms. I've had two in a row in my history. The 16th anniversary of the establishment of the factory was celebrated with two balls. One had factory workers and their families, and the other had guests from the city. In one of them, local games were played and folk songs were sung. There was a lot of dancing in the other. Both stretched until late.

At the factory family's meeting, a game was played that I have never seen before. On one side, the folk song of Köroğlu is sung, two people in the middle are swimming a sheep with steps suitable for this weather. When I say sheep, he is a young man lying on the ground very long and stiff. It's time for the sheep to swim. They inflate it nicely without tearing the man apart. While yours is pretending to be dead, don't they pour a glass of beer into the parts of the wrecker! Until then, the young man, who has endured all parts of the game with great skill, confirms it with lightning speed. He's asking for this bad joke. Turns out there was another game in the game.

A young man, who is the artist of the factory, is pouring jokes that are not stale at all at the microphone. He invites the nightingales of the factory, one by one, to sing at the microphone! They come unnoticed. Some sing ghazals, some of them one of the most fashionable jazz styles… Some of them engage in Köroğlu. Some threshing. Then, the Gıdı Gıdı ball newspaper, which is published every year tonight, is distributed. Inside, there are cartoons made by one of the factory children…”

Here is the truth of Nazilli Sümerbank Press Factory, which surprised Bedri Rahmi Eyüboğlu… One of the most revolutionary steps of the young republic… Nazilli Sümerbank Printed Factory, one of the miracle works of the young republic, which values production, employment, investment, trusts its own people, wants to raise modern individuals who know themselves and the world…

MENTAL DIFFERENCE

Having a very important article about Nazilli Sümerbank Printing Factory, Asst. Assoc. Dr. Is it possible to disagree with Günver Güneş's assessment:

“In addition to its many functions, the factory has been a bridge that introduced the basic concepts of the Republic to the public. Beyond being a factory, Sümerbank has become a school, an educational institution, a place where the teachings of the Republic are put into practice. A factory established in any city in the world, of course, made some changes on that city, but none of them can create as big results as the social, cultural and economic changes that Nazilli Press Factory has created on Nazilli. If this factory, which provides all kinds of opportunities to its employees with the help of the state and brings them economic prosperity, can make its employees read world classics and listen to Beethoven between meals,

Just like the Village Institutes, the giant work of the republic at the beginning of the 1950s, these factories shine a light on Anatolia…

Think about it, that these factories were planted all over Anatolia; Edirne, Manisa, Konya, Tunceli, Diyarbakır… What would Turkey have become? Would the economic, social and political problems experienced today be experienced? To put it simply, would there be a “terrorist scourge” that puts Turkey in more and more financial and moral difficulties with each passing day? Would it be this size though?

After Atatürk, who put aside the "giant projects" such as the Village Institutes, Social Factory, Community Centers, Aircraft Industry, and Railway established by Atatürk and the young republic, who are the chief responsible for the "economic" and "socio-cultural" problems Turkey is experiencing today, in line with the demands of the USA. are powers.

Nazilli Sümerbank Press Factory, which lost blood continuously after the 1950s, received the final blow on November 14, 2002. Nazilli Sümerbank Printing Factory, one of the giant projects of the Republic, was transferred to Adnan Menderes University free of charge by the Privatization Administration. Factory workers were also transferred to Bursa in “tears”. A large part of the factory, whose door was locked, excluding the use of the university, was left to rot with its historical weaving machines, tools and equipment. This gigantic artifact, this gigantic project of the Republic, which would be used as a "museum" and attract millions of tourists, if it were anywhere else in the world, was left to its fate in Nazilli today in a worse condition than the animal barn.

1 It refers to an incident that journalist Banu Avar encountered during her trip to Venezuela. Let's listen to Banu Avar: "While climbing the hill where we will see the city, I was surprised when we passed the Kemal Atatürk sign, and we came to the hill. The young girl guide said excitedly, 'Do you see that factory? Next to it, the wedding hall, that health center, that school, and our house behind it. ' 'Well, I just can't say' The Guide said, 'We call it the ATATÜRK model'.”....

Author: Sinan Meydan

31 December 2010

resources

1. Aslan Buğdaycı, From Past to Present, Nazilli, Istanbul, 2001.

2. Atatürk in Aydın, Aydın, 1981.

3. Aydın Provincial Yearbook, Aydın, 1973.

4. Günver Güneş, “Atatürk's Travels to Nazilli and the Consequences of his Travels”, Atatürk Week Gift, General Staff ATESE Presidency Publications, 10 November 2004, pp.121-135

5. Hulusi Günay, “Nazilli Weaving Factory”, Half Moon, No: 68, 1 İlkkan 1937, p. 8.9 and 19.

6. İbrahim Kiraz, Old City, Nazilli, 2003.

7. L'Ilustration de Turquie, Istanbul.

8. Nazilli Printing Factory Travel Guide, Nazilli, 1937.

9. Nazilli Sümerbank Printing Factory Archive.

10. Saadet Tekin, “Nazilli Press Factory”, History and Society, Vol. 39, P.230, February, 2003.

11. Tahir Kodal, “Mustafa Kemal Atatürk's Travels to Denizli” Atatürk Research Center Journal, Vol. 19, P.55, March 2003.

12. Turkey Trade Post, Special Issue of Nazilli Printing Factory, Ankara, pp. 350-103, 14 July 1948.

13. Zafer Toprak, Sümerbank, Ankara, 1983.

14. Inspections I personally made at the Nazilli Sümerbank Printing Factory in 2010. (Sinan Meydan)

IV

HOW DID THE MUSIC OF THE INDUSTRY BEGIN AND END?

A HISTORICAL LOOK AT SUMERBANK NAZILLI PRINTING FACTORY

Summary

This study deals with the establishment reasons of Sümerbank Nazilli Press Factory and its socio-economic contributions to the country. In addition, the article examines how the factory, which served the country for 66 years, came to a closing point. The main purpose of the article is to draw attention to the mission undertaken by important institutions such as Sümerbank and Etibank in the country by referring to the current economic situation and realities of the country in the example of the Nazilli Press Factory. In this sense, the study emphasizes the importance of questioning ourselves and everything anew at the point of the values entrusted to us by the Great Leader Atatürk, and providing inferences for the future by learning lessons from history on the basis of both businesses and individuals.

1. Introduction

On October 9, 1937, the Great Leader Atatürk is in Nazilli for the opening of the Sümerbank Nazilli Press Factory, and after the victories on the battlefields, they are honoring with their visit to another of the all-out struggle started in the industry. This visit means the beginning of a music that will be played with machines and looms on the way of industrialization and development. Şevket Süreyya Aydemir (1981:379-381) describes the music of the industry, which started playing in Nazilli on October 9, with the following sentences:

“Here the factory was like a headquarters square where teams, companies, battalions lined up for the parade. And like a headquarters square, a command was expected here. The command was not heard, but a silent signal was given from the manager standing behind Atatürk… Atatürk did not expect this at all. He might have thought that when they took him out, maybe they wanted him to see around, maybe say something to the people of the factory. But it wasn't like that, and he was a little startled at first when the world under his feet and the air surrounding him moved so suddenly. Maybe he didn't know what to do. It was a little shaken at first. He pretended to ask something around him. But, at that moment, perhaps without even realizing it, the following words came out of his mouth:

-This is music!..”

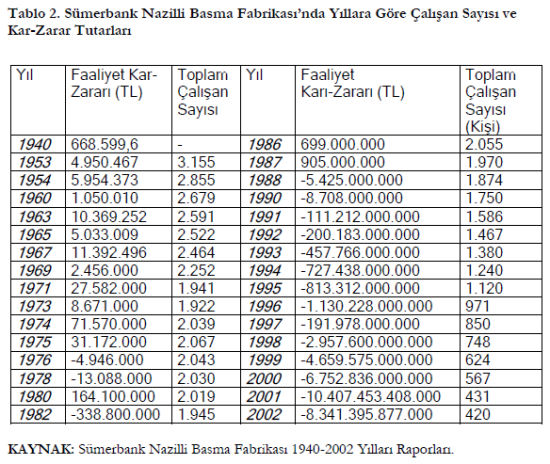

As a matter of fact, Sümerbank Nazilli Basma Factory will perform this music for 66 years without being silent, and will decorate the country with the colorful prints it produces. However, this music, which was played for more than half a century in the factory that Ata opened and gifted to the country with his own hands, will probably disappear in the 2000s, never to be heard again. While the Sümerbank Nazilli Press Factory was virtually wiped out from the scene of life in July 2003, what the factory left behind will remain a legacy worth examining for historians, economists and operators (Doğan, 2007: 105-109).

In particular, the questions why Great Leader Atatürk established this factory during the industrialization process, what the factory contributed to the country's economy in general, and why this factory, like Etibank and other Sümerbank factories, was closed in the 2000s are among the priority issues that need to be answered at the point of making inferences for the future of the country. will take place. Therefore, it should never be overlooked that these and similar studies can be a guide and a source for us to understand and evaluate the importance and target of the economic institutions established in the Republican era much more clearly and objectively.

2. Factors Forming the Ground for the Establishment of the Nazilli Sümerbank Printing Factory

It is not possible to limit the establishment of the Nazilli Sümerbank Printing Factory for one or more reasons. It can be said that many factors, from the economic, political or social conditions of the country to the unique values, conditions, priorities or advantages of the Aegean Region and Nazilli region, were effective in the establishment of the factory. Therefore, it is necessary to gather the factors that paved the way for the formation of the Nazilli Sümerbank Printing Factory on the basis of nation, region and region.

2.1 National Factors

National independence was won with an all-out War of Independence after the First World War, which ended in defeat. In this sense, a very heavy price has been paid for independence, and the new Turkish Republic was built on debt, poverty and hardships. The Great Leader, who knew the situation of the country very well, showed the nation his next goal by saying "There will be no national independence unless there is economic independence" and started an industrialization struggle. Therefore, Nazilli Sümerbank Printing Factory should be considered as a part of this industrialization struggle and plans (Gencosman, 1978: 38-39).

2.2 General Economic Situation of the Country

It is known that the economic situation of the Republic of Turkey after the War of Independence was not very pleasant. There is a country that was devastated by wars and crushed by debts left over from the Ottoman Empire. Especially the Free Trade Agreement signed with England in 1838 was a fatal blow to the Ottoman economy. The goods of the British advanced machinery industry, which entered duty-free, were enough to crush the unprotected handloom industry of the Ottoman Empire in a short time (Sabir, 2003: 1). As a result of the free trade agreements made with many other western countries, the traditional producers in the country could not compete with the products of the western countries that had completed the industrial revolution and disappeared from the economic life. In a short time, the country has become much more importing than exporting.

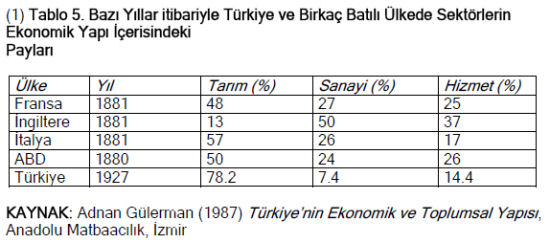

The situation both after the First World War and in the 20s is not much different from this. In 1919, 73% of the 3300 large and small manufacturing industry workplaces working in Western Anatolia were Greeks, and 85% of the 22000 workers in these workplaces were non-Muslims. In addition to the economic difficulties experienced, another indicator in terms of showing the degree of backwardness in industrialization is the sectoral distribution in the country's economy. In 1927, with 78.2%, the agricultural sector was in the first place in the country's economy, followed by the service sector with 14.4% and the industry sector with 7.4%. Unfortunately, even this value is far behind the industrialization rate that many western countries achieved in the mid-1800s. (Gulerman, 1987: 17-18) 1

As a result, the new Republic of Turkey is a country that lagged far behind the West in industrialization, and was established after a war of independence in dire straits, inheriting a large debt legacy from the Ottoman Empire. Therefore, it is inevitable for this newly established country to start an industrialization war in the context of paying the debts taken over on the one hand and restructuring and development on the other. Nazilli Sümerbank Printing Factory also appears to be a concrete extension of this struggle for industrialization and development initiated by the new Turkish Republic throughout the country.

2.3 Weaving Industry in the Country

When we look at the world history, the 18th century of industrialization. We see that it started in the textile industry at the end of the century. As a coincidence, developments in iron-steel, transportation, chemistry, electricity and gasoline engine industry followed at 25-year intervals. In short, textile is the head and locomotive of industrialization. As a matter of fact, it is said that weaving made of cotton fiber was known five thousand years ago at the time of the Egyptian Pharaohs (Gülerman, 1987; 3; Cillov, 1949: 1; Turga, 1947: 6). Therefore, it is a rational step for the new Turkish Republic to start working from textile, which has become the cornerstone of industrialization for the West. Considering the country's traditional production experience and cotton production capacity, it can easily be said that it is an excellent choice, and even a mandatory choice when the general economic texture of the country is considered. As a matter of fact, it is seen that the raw materials processed in the hand looms, whose numbers started to decrease in the last years of the Ottoman Empire, were sold to Europe and then returned to the Ottoman markets after processing. As a matter of fact, the following memory of Hıfzı Velidedeoğlu is enough to summarize the current situation very well (Gülerman, 1987: 9):

“When I was a primary school kid in 1913, one year before the First World War, in a town in Central Anatolia that did not have a train stop, every day with my father, a red fez on our heads, Russian candy among the foods I carried from the market in the floor in our hand; that there was American flour, and that my father had shoes on his feet; French leather and French calico, American cloth for making laundry and clothing on the back; I remember very well looking for German fabric and an Austrian fez to cover my head. My father was looking for these because they didn't have Turkish made ones. It was all coming from outside”.

As a result, at the beginning of the 1900s, there were not enough factories to meet the textile needs of the people in the Ottoman Empire. Those who do generally work to meet the needs of the army. For example, the Defterdar Factory, one of the first factories established in the empire, only meets the fez needs of the army. Similarly, Bakırköy Cloth Factory is our first textile factory established in 1850. However, the total cotton fabric production amount of our fabric factories, which were seven in 1913, consisted of only 3,618,520 meters. Moreover, at the beginning of the 1940s, there were 6250 automatic weaving looms in total in the textile factories in our country, including the Nazilli Sümerbank Printing Factory, while the annual fabric production amount would only reach 120,000,000 meters.

2.4 Economic Policy of the Young Turkish Republic

In the opening speech of the Izmir Economy Congress, which was held between February 17 and March 4, 1923, the Great Leader Atatürk said, “There is a truth left behind by the filter of history and experience. If Turkish history is examined, it is seen that the reasons for the decline and depression are related to economic problems. All the victories won and the failures suffered are related to the economic situation… Our nation has destroyed the enemy armies. There is the following rule for full independence: National sovereignty should be supported by financial sovereignty. The only force that will lead us to this goal is the economy. No matter how great the political and military victories may be, they cannot stand unless they are crowned with economic victories. he underlines that the new struggle in the young Turkish Republic will be on the economic level, and the following decisions taken in the congress provide information about the basics of the policy to be followed in the economic field (Gülerman, 1987: 35-36):

Establishing industrial branches whose raw materials are grown or can be grown domestically,

Transitioning from handicraft and small manufacturing to factories and large enterprises,

Handling the enterprises that cannot be established by the private sector, Establishing a state bank that will provide loans to private enterprises,

Avoiding monopolies established by foreigners,

Wearing local goods

Encouragement of industry and establishment of national banks,

Establishment of railway and road network,

Employers are called workers, not workers, and the right to unionize is recognized.

As a result, it can be said that the decisions taken at the Izmir Economic Congress drew the direction of the new Turkish Republic's economic movement, and in this respect, it could be said that it formed the infrastructure for the First Five-Year Industrial Plan of the Republic (1933-1937). In other words, the First Five-Year Industrial Plan can also be described as the transition phase of the decisions taken at the Izmir Economics Congress into action. As a matter of fact, in the said plan;

* Which is included in our imports, but which will not have any foreign dependency in its production due to the possibility of supplying its raw materials from within the country,

* If some raw materials are imported, the rest of the production can be realized domestically,

The emphasis was placed on the establishment of industrial units based on state resources, and the industrial investments to be made within this scope were grouped into five groups in total: weaving, mining, cellulose, ceramics and chemical industries. During the implementation of the projects included in the said plan, Sümerbank was given important duties. Established in 1933 as an economic state enterprise instead of Turkey Industry and Maadin Bank and Turkish Industry and Credit Banks, Sümerbank, Kayseri Cloth Factory, Izmit Paper and Chemical Industry Factories, Nazilli Basma Factory, Merino Wool Factory, Gemlik Artificial Silk Factory, which are within the scope of the First Five-Year Industry Plan. He played an important role in the realization of the Karabük Iron and Steel Factories with his factory.

2.5 Regional Factors

We see that the new Government of the Republic of Turkey takes very meticulous and careful steps in all projects and decisions related to economic investments, as in every field. So much so that in the early 1930s, the government was not content with an expert team coming from the Soviet Union to work and report on the facilities to be established, but also invited another group of experts from the United States to work (Tezel, 2006). In short, it is unthinkable that the Republican Government, which is extremely sensitive to the issues that will determine the economic future of the country, may have left the places of the newly established factories to chance.

2.5.1 Agricultural Infrastructure of the Region and Cotton

It is clear that the Aegean Region, with its Bakırçay, Gediz, Küçük and Büyük Menderes, Balıkesir and Akhisar plains, is an agricultural paradise. This region has been the apple of everyone's eye throughout history with its products ranging from figs to grapes, from olives to cotton. The situation in the Republican period is not different from this. The region is one of the most important cotton growing areas of the country, together with Çukurova, as it was in the Ottoman Empire. However, the vast majority (80%) of the cotton produced is sent abroad as raw, and the local people are trying to produce only on hand looms to meet their own needs (Tekin, 2003: 20). Therefore, in the context of the principle of “establishing branches of industry whose raw materials are grown or can be grown domestically” both in the Izmir Economy Congress and in the First Five-Year Industry Plan, The establishment of a textile combination in the Aegean Region, which can be considered as the homeland of cotton in Turkey, will be considered both a rational and a mandatory step. Sümerbank Nazilli Press Factory should also be evaluated as a result of this necessity and rational approach.

2.5.2 Existing Road Network of the Region and Its Importance

It is known that one of the most important factors determining the establishment location of the enterprises, such as proximity to raw materials and the market, is the existing transportation facility and road network. As a matter of fact, it is unthinkable that the government can ignore this criterion when choosing the location of the state factories to be established. Already in those years, we see that the Aegean Region had a railway network, which we can say quite broad in general. It is even known that the Izmir-Aydin line is the oldest railway line of the Republic of Turkey. Moreover, as of the beginning of the 1900's, it is seen that the Aegean Region was surrounded by the İzmir-Afyon and İzmir-Eğridir railway lines (Yerasimos, 1980: 526). Another factor that makes the Aegean Region advantageous is that these railway lines are connected to Izmir Port. In short, the railway line of the Region is almost integrated with sea transportation, is integrated. In other words, the two traditional and cheapest transportation methods in the world are connected to each other in this region.

2.5.3 Social Structure of the Region: Population

The factory to be established will be a source of employment and bread for thousands of people. Therefore, there should be no problems in the employment of the employee. From this point of view, there is no such problem in the Aegean Region and Nazilli. So much so that, right next to Nazilli, there are Aydın (45 km), Denizli (81 km), and even İzmir (175 km), which was the second largest province in terms of population in those years. Although Nazilli was behind these provinces in terms of population in those years, the surrounding provinces and districts could be a source of employment for Nazilli, as Nazilli is at the center point and there is no significant problem in the transportation infrastructure. As a matter of fact, with the opening of the Factory, Nazilli will leave Denizli behind in terms of population, let alone the surrounding provinces from every region of Turkey such as the Black Sea, Marmara and Mediterranean,

2.6 Local Factors

It is known that there was a conflict between the people of Aydın, Denizli and Nazilli before the location of the new factory to be established was determined. However, it is obvious that Nazilli has a number of advantages compared to others. As a matter of fact, this advantage did not go unnoticed by the government of that day, and it was significantly effective in determining the place of establishment.

2.6.1 Nazilli Cotton Station

One of the most important local factors that can be said to be decisive in the establishment of the Printing Factory in Nazilli is the establishment of a Cotton Station here in 1934. Shortly after the proclamation of the Republic, the government took action to increase the quality and productivity in agriculture and to put scientific projects, research and applications into practice. In this sense, a Seed Improvement Commission was established in Adana in 1925 as the first job in cotton production. Experiments were made by bringing 40 kinds of seeds from America, and not satisfied with this, experts in the field of cotton production were invited to our country from abroad. Cleveland for Cukurova by experts, In line with the report that Akala type cotton would be suitable for the Aegean region, the Ministry of Agriculture took action and prepared a cotton cultivation plan, and in this framework, Nazilli Cotton Station was established in 1934. The government, which is based on science and quality in every field, not only brought some advanced machinery from abroad to the station by being meticulous at this point, but also appointed Celal İğriboz, who had completed his education in the USA, as the head of the institution. Celal İğriboz worked and struggled here for years and became the leader and doyen of the cotton cause in the Aegean Region. So much so that after dealing with cotton dust, he finally got a serious and terrible disease and died for this cause (Tekin, 2003: 20-26; Yazman, 1940: 5). The government, which is based on quality in every field, not only brought some advanced machinery from abroad to the station by being meticulous at this point, but also appointed Celal İğriboz, who had completed his education in the USA, as the head of the institution. Celal İğriboz worked and struggled here for years and became the leader and doyen of the cotton cause in the Aegean Region. So much so that after dealing with cotton dust, he finally got a serious and terrible disease and died for this cause (Tekin, 2003: 20-26; Yazman, 1940: 5). The government, which is based on quality in every field, not only brought some advanced machinery from abroad to the station by being meticulous at this point, but also appointed Celal İğriboz, who had completed his education in the USA, as the head of the institution. Celal İğriboz worked and struggled here for years and became the leader and doyen of the cotton cause in the Aegean Region. So much so that after dealing with cotton dust, he finally got a serious and terrible disease and died for this cause (Tekin, 2003: 20-26; Yazman, 1940: 5).

Nazilli Cotton Station started to bear fruit shortly after its establishment and in 1936, 21,000 kilos of Akala seeds were distributed only to Nazilli and its surroundings. As a result of the brilliant results obtained, a significant amount of cotton seeds were given to the surrounding provinces in the following years. As a result, the establishment of a textile combination at the point where the Menderes Plain, which is the land of cotton, and the cotton station, which is the main source for the seed needs of this plain and surrounding provinces, are located, seems to be a rational choice today, as it was then. 2

2.6.2 Coal, Water and Energy Resources